Abstract

Novel gel polymer electrolytes (GPEs) based on guar gum and lithium bis(oxalate)borate (LiBOB) were developed via the dissolution method. Structural and ionic conductivity properties were investigated using Fourier-transform infrared (FTIR) spectroscopy, differential scanning calorimetry (DSC), and electrochemical impedance spectroscopy (EIS). FTIR analysis revealed significant interactions between guar gum and LiBOB. DSC results indicated a decrease in both the glass transition temperature (Tg) and crystallization temperature (Tc) with increasing LiBOB content, reflecting enhanced amorphous phase formation. An optimum ionic conductivity of 7.89 × 10−4 S cm−1 at room temperature was achieved with 6 wt. % LiBOB. The temperature dependence of conductivity followed Arrhenius behavior, suggesting thermally activated ion transport. FTIR deconvolution established a correlation between the number density, mobility, and diffusion coefficient of mobile ions with ionic conductivity. These findings demonstrate the potential of guar gum–based GPEs for lithium-ion battery applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The development of efficient and sustainable energy storage systems has become increasingly essential due to the rising demand driven by electric vehicles and portable electronic devices. A critical component of these systems is the electrolyte, which facilitates ion transport between electrodes. Traditionally, liquid electrolytes have been preferred due to their superior conductivity and electrochemical properties. However, these electrolytes have notable disadvantages, such as electrode corrosion, high dendrite growth, and the risk of leakage, posing threats to both human health and the environment. Such limitations make them less than ideal for electrochemical applications [1]. The transition to polymer electrolytes (PEs) offers improved safety, sustainability, and potentially lower production costs [2]. Key attributes of effective polymer electrolytes include high ionic conductivity at room temperature, thermal stability, mechanical robustness, a high transference number, a broad electrochemical window, and good electrode compatibility [3].

Polymer electrolytes are typically classified into three categories: solid polymer electrolytes (SPEs), composite polymer electrolytes (CPEs), and gel polymer electrolytes (GPEs) [4]. SPEs offer advantages such as easy processing, no leakage, and prevention of dendrite formation. They also possess a wide electrochemical window and are lightweight, making them attractive for energy storage applications [5]. Despite these benefits, their limited ionic conductivity at room temperature, typically in the range of 10⁻⁸ to 10⁻⁶ S cm⁻1, restricts their practical use in devices [6]. On the other hand, CPEs show improvements in conductivity and mechanical properties but often suffer from high interfacial resistance between the electrode and electrolyte, hindering ion transport [7]. GPEs, a hybrid between solid and liquid electrolytes, overcome many of these issues. They offer high ionic conductivity (10⁻4 to 10⁻3 S cm⁻1) while retaining the mechanical stability of solid electrolytes and reducing the risk of leakage [8].

The emphasis on biodegradable materials for gel polymer electrolytes (GPEs) has increased due to their environmental benefits and suitability for sustainable energy storage applications. Biopolymers sourced from plants and microorganisms, such as starch, alginate, agar, cellulose, chitosan, carrageenan, and polylactic acid (PLA), offer desirable attributes including good mechanical properties, flexibility, and ionic conductivity [9,10,11,12,13]. These cost-effective materials support the global shift towards green technologies in energy storage systems, extending beyond electrolyte synthesis to electrode fabrication as well. For instance, Minakshi et al. recently utilized honeydew peel and comb materials to develop electrodes for electric double-layer capacitors (EDLCs) [14, 15].

Guar gum (GG), a biodegradable and non-toxic polymer, serves as the polymer host in this study. It is composed of β−1,4-linked mannose units and α−1,6-linked galactose units, giving it its unique properties. Guar gum’s high molecular weight and gel-forming abilities make it a promising candidate for polymer electrolytes. Additionally, its low cost makes it economically feasible for large-scale applications, such as stabilizing agents in GPEs [16]. In this research, guar gum is combined with 1-butyl-3-methylimidazolium chloride ([Bmim]Cl) to produce materials with enhanced electrochemical properties. Gel polymer electrolytes have been a subject of extensive research due to their desirable physicochemical properties, particularly when doped with ionic salts [17]. Lithium salts like LiClO₄, LiBF₄, LiAsF₆, LiCF₃SO₃, and others have been studied for their use in GPEs. However, many of these salts present issues, including explosiveness, toxicity, poor solid electrolyte interphase (SEI) formation, and corrosiveness [18]. Lithium bis(oxalate)borate (LiBOB) stands out as a more favorable option, as it facilitates the formation of a stable SEI and meets other critical requirements for polymer electrolytes [19,20,21]. This work investigates the structural and ionic transport properties of GPEs based on guar gum and LiBOB. The characterization includes Fourier-transform infrared (FTIR) spectroscopy, differential scanning calorimetry (DSC), and impedance spectroscopy (EIS), offering insights into the material’s potential for energy storage application.

Recently, The PMMA-PLA-based electrolytes have been studied for their stability and performance in electrochemical applications, compared to the PMMA-PLA HGPEs with LiTFSI and BmimCl, the guar gum–based LiBOB electrolyte offers a more sustainable, unlike synthetic polymers such as PMMA and PLA, guar gum is a natural, renewable polysaccharide, offering environmental and sustainability benefits. The complexation of lithium ions (Li⁺) from LiBOB with the carboxylate (-COO⁻) groups in the guar gum backbone potentially enhances thermal stability, making it more suitable for high-temperature applications compared to PMMA-PLA systems. While the PMMA-PLA system achieves high ionic conductivity (1.63 × 10⁻3 S cm⁻1) and a stability window of 3.4 V [22], the guar gum-LiBOB system could provide comparable conductivity and superior heat resistivity, making it well-suited for applications demanding both electrochemical performance and environmental sustainability.

Experimental

Preparation of bio-based polymer (BBPEs) electrolytes

The GPE films consist of guar gum and [Bmim]Cl, which were obtained from Sigma-Aldrich, with molecular weights of approximately 535.15 g/mol and 174.67 g/mol, respectively. To prepare the sample, the gel polymer electrolytes (GPEs) were synthesized using the dissolution method. Guar gum was dissolved in a [Bmim]Cl solution at a guar gum-to-[Bmim]Cl weight ratio of 1:5 (0.2 g guar gum in 1.0 g [Bmim]Cl). The mixture was stirred vigorously at 30 °C until a homogeneous solution was achieved. LiBOB was added as a dopant (2–12 wt.%) and the mixture was stirred further. The solution was then heated at 80 °C for 4 h to form a gel-like polymer, cooled at room temperature for 30 min, and treated under vacuum. It was purged with argon to create an inert atmosphere and placed in a desiccator to ensure solvent purity. A summary of the sample preparation, designations (for different compositions), and physical appearances of the BBPEs is shown in Fig. 1.

Characterization of bio-based polymer electrolytes (BBPEs) system

Fourier-transform infrared (FTIR)

FTIR spectroscopy was utilized to examine the interaction within the GG-LiBOB system at ambient temperature. A Perkin Elmer 100 Fourier-transform infrared (FTIR) spectroscope with an attenuated total reflection (ATR) accessory equipped with ZnSe crystal was used. The sample was tested within the frequency range of 4000 to 700 cm−1 with a resolution of 2 cm−1.

Differential scanning calorimetry (DSC)

The glass transition temperature (Tg) and crystallization temperature (Tc) of the GPEs was measured using a Netzsch Polyma 240 DSC. The sample, weighing about 10 mg, was placed in an aluminum cell and analyzed with a heating rate of 10 °C/min. The measurement covered a temperature range of 0–400 °C under a nitrogen flow rate of 20 ml/min, with an empty pan as the reference.

Electrical impedance spectroscopy (EIS)

The prepared samples underwent alternating current (AC) impedance spectroscopy for thorough analysis. These samples were meticulously placed into stainless-steel coin cell–blocking electrodes to maintain consistent sample diameters and were then secured within a battery jig cell. The measurements were performed at controlled ambient temperatures within an oven under inert conditions to preclude any moisture ingress. The bulk resistance (Rb) value was obtained from the imaginary impedance (− Zi) versus real impedance (Zr) of the Nyquist plot using a HIOKI 3532–50 LCR Hi-TESTER over a frequency spectrum ranging from 50 Hz to 1 MHz, and the ionic conductivity (σ) was subsequently calculated using the following equation:

where t (cm) is the thickness, A (cm2) is the electrode–electrolyte contact area, and Rb (Ω) is the bulk resistance of GPEs system which can be obtained from the Cole–Cole plot of EIS.

Result and discussion

FTIR spectroscopy studies

Fourier-transform infrared (FTIR) spectroscopy was employed to examine the interactions within the guar gum-LiBOB gel polymer electrolytes (GPEs). This analysis focuses on identifying any ion-polymer interactions, molecular structure, and possible changes in peak intensity or shifts, which signify interactions within the polymer matrix. FTIR is an essential tool for studying the chemical composition and interactions within GPEs, as it provides insight into the formation and behavior of the gel structure when liquid electrolytes are solidified using polymers. Figure 2 illustrates the FTIR spectra of the individual components: guar gum (GG), lithium bis(oxalate)borate (LiBOB), and 1-butyl-3-methylimidazolium chloride ([Bmim]Cl). Each constituent displays characteristic peaks representing its functional groups, which form the basis for understanding the interactions within the final GPE system.

Guar gum shows a broad O–H stretching band between 3600 and 3300 cm⁻1, indicative of hydroxyl groups. A distinct peak at 1637 cm⁻1 is attributed to O–H bending vibrations, and the peak at 1015 cm⁻1 corresponds to C–O–C stretching, representative of the (1–4) linkage in galactose units. LiBOB exhibits a prominent C = O stretching vibration at 1811 cm⁻1, which is essential for understanding its role in the polymer matrix. This peak reflects the carbonyl group’s interaction with lithium ions in the system. [Bmim]Cl demonstrates several notable peaks: O–H stretching at 3382 cm⁻1, C–H stretching at 2925 cm⁻1, and C–N stretching in the imidazolium ring at 1564 cm⁻1. Table 1 further details the peak assignments for each material, including their corresponding wavenumbers and functional groups based on literature references. These assignments serve as a reference for detecting shifts or changes in the GPE system, indicating interactions between the polymer, solvent, and dopant.

Figure 3 illustrates the FTIR spectra for the GPE samples (S0 to S6) over the overall range of wavenumbers, highlighting the changes in key functional groups as the LiBOB concentration increases. In the un-doped sample (S0), characteristic peaks for guar gum, including O–H stretching at 3377 cm⁻1, O–H bending at 1635 cm⁻1, and C–O–C stretching at 1090 cm⁻1, are clearly visible. As the concentration of LiBOB increases, these peaks shift progressively, indicating significant interactions between the lithium ions and the polymer matrix. The O–H stretching peak shifts to lower wavenumbers (3374 cm⁻1 in S6), suggesting that Li⁺ ions interact more strongly with the hydroxyl groups. Similarly, the C = O stretching peak appears and shifts upward from 1698 cm⁻1 in S1 to 1711 cm⁻1 in S6, signifying enhanced coordination between Li⁺ ions and the carbonyl groups in the polymer. Table 2 summarizes these changes in the vibrational modes for the GPE samples, showing how the peak positions shift as LiBOB is introduced. The shifts in O–H and C–O–C stretching, along with the appearance and shift of the C = O stretching peak, highlight the increasing interaction between lithium ions and the polymer’s functional groups. These interactions strengthen the bonds within the polymer matrix and improve its structural order, which is crucial for enhancing the electrochemical performance of the GPE system. The gradual changes in the spectra confirm that LiBOB plays a key role in modifying the polymer’s structural and ionic conduction properties.

\({\nu }_{as}\) asymmetric stretching, \(\delta\) bending vibration, \(\omega\) wagging, \(\tau\) twisting, \(\rho\) rocking.

Figure 4 highlights the significant shifts in wavenumber observed in the FTIR spectra of the guar gum-LiBOB–based GPEs as the concentration of LiBOB increases. These shifts provide critical evidence of interactions between lithium ions and functional groups within the polymer matrix. In Fig. 4a, the C = O bending peak shows a clear shift from 1698 cm⁻1 in S1 to 1711 cm⁻1 in S6. This upward shift can be attributed to the increasing concentration of LiBOB, which strengthens the interaction between the lithium ions and the carbonyl groups. The pronounced interaction leads to a strengthening of the C = O bond, causing its vibrational energy to increase, resulting in the shift to a higher wavenumber [35]. Additionally, the OH bending peak, initially detected at 1635 cm⁻1, undergoes a gradual shift to 1656 cm⁻1 as the concentration of LiBOB increases. This shift is indicative of enhanced coordination between Li⁺ ions and the hydroxyl groups, which increases the electron density around the OH groups and strengthens the O–H bond. Consequently, this enhanced bonding increases the vibrational energy of the O–H groups, causing the peak to shift to a higher wavenumber [36].

The interaction of LiBOB not only affects the bonding within the polymer matrix but also improves its structural order, as evidenced by the more defined and intense spectral peaks. These changes reflect significant alterations in the electronic and vibrational environment of the OH groups due to the coordination of lithium ions, which enhances dipole moments and increases infrared absorption. In Fig. 4b, the C–O–C stretching peak shifts from 1090 cm⁻1 in S0 to 1094 cm⁻1 in S6. This shift can be explained by the introduction of more Li⁺ ions into the polymer matrix, leading to stronger or more numerous interactions between Li⁺ ions and the ether oxygen atoms. As Li⁺ ions interact with the ether oxygen, the C–O–C bond tightens, which in turn causes an increase in vibrational frequency. This phenomenon suggests that higher concentrations of LiBOB result in greater ionic association, altering the electronic environment around the C–O–C bonds and shifting their vibrational frequencies [37]. These wavenumber shifts in both the C = O and C–O–C regions demonstrate how the coordination of lithium ions with the polymer matrix influences the molecular structure and bonding within the GPEs, contributing to their enhanced conduction properties.

Figure 5 illustrates the intensity changes observed in the FTIR spectra as the composition of LiBOB increases in the guar gum–based GPE system. In Fig. 5a, a noticeable decrease in the intensity of the O–H stretching peak at 3331 cm⁻1 is observed. This reduction in intensity is attributed to the interaction between lithium ions (Li⁺) and the hydroxyl groups (O–H) in guar gum. As the concentration of LiBOB increases, more Li⁺ ions are available to coordinate with the oxygen atoms of the hydroxyl groups, disrupting the pre-existing hydrogen bonding network. This disruption reduces the number of free O–H groups capable of independent stretching, which leads to a decrease in the O–H stretching intensity. The interaction between Li⁺ ions and the hydroxyl groups alter the vibrational characteristics of these groups, reflecting the extent of coordination within the polymer matrix [38].

Conversely, Fig. 5b shows an increase in the intensity of the C–O–C stretching peak as LiBOB concentration increases. This increase can be explained by the coordination of Li⁺ ions with the ether oxygen atoms in the pyranose rings of guar gum. The coordination between Li⁺ ions and these oxygen atoms strengthens the C–O–C bonds, leading to an increase in their vibrational energy and a shift of the peak to a higher wavenumber. The enhanced interaction also increases the dipole moment of the C–O–C bonds, resulting in greater infrared absorption and a more intense peak. This coordination contributes to the stabilization of the polymer structure, which is crucial for improving the overall electrochemical performance of the GPE system [24, 39].

Figure 6 provides a schematic representation of the ion transport mechanism within the GPE system. The figure depicts how Li⁺ ions interact with the oxygen atoms of the hydroxyl groups and the ether oxygen atoms in the polymer matrix via ion–dipole interactions. As Li⁺ ions move through the system, they coordinate temporarily with these oxygen atoms, facilitating ion transport through an ion-hopping mechanism. Unlike the Grotthuss mechanism, which applies to proton conduction, Li⁺ transport in this system involves hopping between available coordination sites within the polymer matrix. The mobility of Li⁺ ions is closely tied to the dynamic motion of the polymer chains, which create free volume and allow for the continuous movement of ions from one coordination site to another. This ion-hopping mechanism is crucial for enhancing the ionic conductivity of the GPE system. As the polymer matrix undergoes segmental motion, it enables Li⁺ ions to move between coordination sites, facilitating efficient ion transport. The ability of Li⁺ ions to coordinate with both O–H and C–O–C groups within the polymer matrix ensures that ion conduction occurs smoothly, contributing to the overall conductivity of the system. The interactions between Li⁺ ions and the polymer’s functional groups, as depicted in Fig. 6, are fundamental to the system’s enhanced conduction performance [40, 41].

Differential scanning calorimetry (DSC)

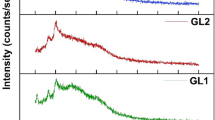

The thermal properties of the guar gum-LiBOB gel polymer electrolytes (GPEs) were investigated using differential scanning calorimetry (DSC), as shown in Fig. 7. These figures depict the phase transitions within the polymer matrix, particularly focusing on the glass transition temperature (Tg) and crystallization temperature (Tc). The glass transition temperature (Tg) is a critical parameter that marks the transition of the polymer from a rigid, glassy state to a more flexible, rubbery state, providing insight into the polymer’s molecular mobility under varying conditions [42]. Figure 7 shows the DSC thermograms of GPEs with different LiBOB compositions, where the broad humps represent both the glass transition and crystallization behavior of the samples.

A notable observation is the reduction in Tg with increasing LiBOB content. For the undoped sample (S0), the Tg is recorded at 72.9 °C. Upon the addition of LiBOB, the Tg drops significantly, reaching 62.6 °C in the S3 sample (with 6 wt.% LiBOB). This reduction suggests that LiBOB enhances the flexibility of the polymer matrix by disrupting the interactions between the polymer chains, which increases segmental mobility and facilitates ionic conduction. This observation is consistent with Ajeet Kumar et al., who noted that the presence of ionic liquids (ILs) reduces Tg due to their plasticizing effect [43]. In this case, LiBOB acts as a plasticizer, lowering the rigidity of the polymer matrix and increasing flexibility. This effect is especially prominent in the S3 sample, which demonstrates optimal flexibility, making it a promising candidate for advanced GPE applications. The enhanced segmental mobility reduces the dipole–dipole interactions between Li⁺, BOB⁻ ions, and the polymer backbone, promoting ion dissociation and transport [44].

Figure 8 further illustrates the glass transition behavior across the selected GPEs, confirming that the sample with the highest LiBOB content (S3) has the lowest Tg. This reduced Tg is crucial as it correlates with the increased amorphous character of the polymer matrix, which in turn enhances ionic conductivity. The incorporation of LiBOB weakens the crystalline regions of the guar gum polymer, leading to a more amorphous structure and a lower Tg, which facilitates the dissociation and mobility of Li⁺ ions within the matrix. This observation aligns with the theory that a lower Tg generally improves polymer chain packing and contributes to enhanced ion transport within GPE systems. The crystallization temperature (Tc) values for each GPE sample, as shown in Table 3, reveal that higher LiBOB concentrations increase the Tc, indicating that the system’s thermal stability improves with the addition of LiBOB.

Figure 9 illustrates the crystallization temperature (Tc) of the selected guar gum-LiBOB GPE samples, which is a key indicator of the polymer’s structural order and thermal stability. In the pure guar gum sample (S0), the Tc is 290.2 °C, representing the baseline behavior of the unmodified polymer. The addition of 2 wt.% LiBOB in the S1 sample increases the Tc to 313.9 °C, indicating stronger ionic interactions and enhanced structural order. This increase suggests that the incorporation of LiBOB leads to a more thermally stable matrix due to improved interactions between the lithium ions and the polymer. Interestingly, the Tc decreases to 281.4 °C in the S3 sample (with 6 wt.% LiBOB), indicating a more amorphous structure at this concentration. This decrease suggests that at this composition, the gel polymer becomes less ordered, likely due to increased segmental motion and disorder in the polymer chains. This increased disorder enhances ionic mobility, facilitating better ion transport and contributing to higher ionic conductivity. However, for the S4 sample, the crystallization temperature (Tc) increases to 302.1 °C, indicating a transition back to a more ordered structure as the concentration of LiBOB increases. The enhanced ionic interactions at higher LiBOB concentrations lead to a more crystalline arrangement, which may restrict ionic mobility [45].

Ionic conductivity studies

Figure 10 presents the ionic conductivity of guar gum-based gel polymer electrolytes (GPEs) as a function of LiBOB concentration at ambient temperature. The ionic conductivity shows a noticeable increase as the LiBOB content rises, peaking at 6 wt.% with a maximum conductivity of 7.89 × 10⁻4 S cm⁻1. This enhancement can be attributed to the effective dissociation of Li⁺ cations and BOB⁻ anions within the guar gum matrix, which facilitates the movement of charge carriers through the system [46]. The rise in ionic conductivity is driven by two primary factors: (1) the segmental mobility of the polymer chains, which governs the dynamics of ion transport, and (2) the concentration of free mobile ions that are influenced by the interaction between Li⁺ ions and the polymer’s functional groups [41]. As observed in the FTIR results, Li⁺ ions interact with the ether oxygen atoms in the pyranose rings of guar gum, promoting ion–dipole interactions that enhance the pathways for ion conduction.

The highest ionic conductivity at 6 wt.% LiBOB reflects the optimal balance between the number of charge carriers and their mobility within the polymer matrix. At this concentration, the guar gum matrix is flexible enough to support efficient ion migration due to increased segmental motion, as also indicated by the lower Tg and Tc values in the DSC analysis. This flexibility enhances the dissociation of Li⁺ ions, promoting higher conductivity [47] However, when the LiBOB content exceeds 6 wt.%, the ionic conductivity begins to decline. This reduction is attributed to the formation of neutral ion pairs or aggregates, where Li⁺ cations and BOB⁻ anions neutralize each other, reducing the number of free ions available for conduction [48]. The formation of these ion pairs limits the participation of ions in electrical conduction, thus impairing the overall ionic mobility [49]. Additionally, higher concentrations of LiBOB can lead to phase separation or non-uniform distribution of the salt, increasing the viscosity of the gel and further hindering ion mobility [50]. This phenomenon indicates that beyond 6 wt.% LiBOB, the system becomes too rigid, reducing the effectiveness of ion transport and lowering ionic conductivity.

The relationship between ionic conductivity and temperature for the guar gum–based gel polymer electrolytes (GPEs) doped with LiBOB is illustrated in Fig. 11. The conductivity of all GPE samples increases with rising temperature, showing a linear dependence, which confirms that the system follows Arrhenius behavior. This behavior is typically observed in thermally activated processes, where ionic mobility improves with temperature due to enhanced segmental motion and free volume within the polymer matrix [51]. The linear trend without any abrupt jumps indicates that the GPE system exhibits amorphous behavior, as there is no sharp crystallization that would hinder ion transport [52]. The FTIR results support this observation by showing how Li⁺ ions interact with the functional groups in the guar gum matrix (e.g., O–H and C–O–C groups), which form ion–dipole interactions that facilitate ion movement. The enhanced mobility of Li⁺ ions along these conduction pathways, as temperature increases, aligns with the increased ionic conductivity. As temperature increases, Li⁺ ions can move more freely through conduction pathways formed by the polymer chains of guar gum, enhancing the overall ionic conductivity. The high regression values (R2 ~ 0.99) for all samples further confirm that the conductivity-temperature relationship is well described by the Arrhenius equation

where σ is the ionic conductivity, σo is the pre-exponential factor, Ea is the activation energy, k is the Boltzmann constant, and T is the temperature. From this equation, Ea can be determined by calculating the slope of the plot of log σ versus 1000/T.

Figure 12 shows the activation energy (Ea) values for the guar gum-LiBOB GPE system with varying LiBOB compositions. The trend in Ea is inversely related to ionic conductivity. As LiBOB content increases up to 6 wt.%, the Ea decreases, reaching a minimum value in the S3 sample, which also exhibits the highest ionic conductivity. The DSC data aligns with this observation, as the lower Tg in the S3 sample reflects enhanced chain mobility, which helps to reduce the energy barrier for ion conduction [53]. This reduction in Ea suggests that LiBOB enhances the concentration of mobile Li⁺ ions, thereby lowering the energy barrier for ion migration and facilitating easier ion transport within the polymer matrix. Additionally, LiBOB likely modifies the polymer network structure, creating more efficient pathways for ion conduction and improving the solvation of lithium ions. However, beyond 6 wt.% LiBOB, the Ea increases, which corresponds to a decline in ionic conductivity. This rise in Ea can be attributed to reduced polymer chain mobility and the formation of obstructive pathways that hinder ion transport, limiting the overall conductivity of the GPE system [54].

Li + transport properties

The transport properties of the guar gum–based gel polymer electrolytes (GPEs) were evaluated through ATR-IR deconvolution, as shown in Fig. 13. This method was employed to gain a deeper understanding of the ion dissociation and association behaviors within the GPE system. In particular, the spectral region between 1105 and 1075 cm⁻1 was deconvoluted to distinguish between free ions and contact ions. The peaks at 1086 cm⁻1 and 1090 cm⁻1, corresponding to the O–B–O symmetric stretching from the LiBOB salt and the C–O–C stretching from the guar gum polymer host, were identified as key indicators of ionic interactions within the GPE matrix [55, 56]. The deconvolution process revealed two distinct types of ions: free ions and contact ions. Free ions are mobile and contribute directly to ionic conduction, while contact ions are those that are more strongly associated with the polymer matrix or other ions, forming ion pairs or aggregates. The free ions are primarily located around the peak at 1091 cm⁻1, representing ions that are dissociated and available for conduction. In contrast, the contact ions are located around the peak at 1097 cm⁻1, indicating ions that are more strongly associated with the polymer or form ion pairs, reducing their mobility. The presence of these two ion types provides critical insights into the conduction mechanism within the GPE system.

The OriginPro 9.0 was utilized with nonlinear least squares fitting to achieve peak deconvolution. The relative percentages of free ions and contact ions are derived from the areas of the deconvoluted peaks corresponding to specific ions, calculated using the following equation,

where \({A}_{f}\) denotes the area of the peak corresponding to the free ions’ region, and Ac represents the cumulative area of the peaks attributed to contact ions.

This approach allowed for a precise calculation of the ratio between free and contact ions across the various GPE samples (S1–S6), as depicted in Fig. 13 and tabulated in Table 4. The analysis revealed that the addition of LiBOB enhances ion dissociation up to a certain concentration (around 6 wt.% LiBOB in the S3 sample), which maximizes the number of free ions. This increase in free ions corresponds to the higher ionic conductivity observed in earlier results. As the concentration of LiBOB increases beyond this point, however, the proportion of contact ions also increases, indicating the formation of ion pairs or aggregates, which reduce the number of free charge carriers and, consequently, the ionic conductivity [57, 58].

Figure 14 illustrates the number density (η), mobility (μ), and diffusion coefficient (D) of mobile ions across various concentrations of LiBOB, calculated based on the quantities of salt used during preparation and supported by data from FTIR deconvolution studies. These transport parameters are essential for understanding the behavior of ion conduction within the guar gum–based gel polymer electrolyte (GPE) system and show trends that align closely with the observed ionic conductivity.

The number density (η), representing the concentration of mobile ions, increases with rising LiBOB content, reaching its peak at 6 wt.% (S3). This increase in mobile ion concentration can be attributed to enhanced dissociation of Li⁺ ions facilitated by interactions with the ether groups (C–O–C) of the guar gum polymer, as observed in the FTIR analysis. The increased dissociation results in a higher number of charge carriers, which directly contributes to improved ionic conductivity [37]. This trend is reinforced by the corresponding rise in both mobility (μ) and diffusion coefficient (D), which are crucial parameters for the efficient transport of ions within the GPE matrix. The creation of additional vacancies within the polymer matrix at 6 wt.% LiBOB provides enhanced pathways for ion transport, facilitating both the mobility of Li⁺ ions and their diffusion through the system [59].

The DSC analysis further supports these findings by indicating lower Tg and Tc values in the optimal GPE, confirming that the amorphous structure of the polymer enhances the dissociation of Li⁺ and BOB⁻ ions. This enhanced distribution of ions throughout the polymer matrix promotes higher diffusion rates and, consequently, improves ionic conductivity. The increased diffusion coefficient (D) and ion mobility (μ) up to 6 wt.% LiBOB demonstrate that this composition provides the most favorable conditions for ion transport [60]. However, beyond the optimal concentration (S3), the system becomes overcrowded with excess lithium ions, leading to a decrease in the number of effective charge carriers. The trapped ions, requiring more energy to move through the increasingly constrained polymer matrix, result in reduced mobility and diffusion. As a result, the number of free charge carriers begins to decline due to the formation of ion aggregates or neutral ion pairs at higher LiBOB concentrations. This aggregation hinders ion mobility, limiting the overall conductivity of the system [34]. Thus, the observed trends in transport properties—number density, mobility, and diffusion coefficient—are closely aligned with the ionic conductivity trends, emphasizing their critical role in optimizing lithium-ion coordination within the GPE system.

Conclusion

In this present work, a series of novel gel polymer electrolytes (GPEs) incorporating varying concentrations of lithium bis(oxalato)borate (LiBOB) salt were synthesized and extensively characterized. Fourier-transform infrared (FTIR) spectroscopy revealed notable interactions between the polymer host (guar gum) and Li⁺ ions, as evidenced by shifts in the OH stretching, OH bending, and C–O–C bonds. Differential scanning calorimetry (DSC) confirmed the amorphous nature of the GPE system, with significant reductions in both the glass transition temperature (Tg) and crystallization temperature (Tc) for samples with higher LiBOB content, indicating enhanced polymer flexibility and improved ionic transport properties. Among the samples, the GPE containing 6 wt.% LiBOB (S3) exhibited the highest ionic conductivity of 7.89 × 10⁻4 S cm⁻1 at ambient temperature. All GPE samples followed Arrhenius behavior, with the lowest activation energy (Ea) of 0.31 eV observed for the S3 sample, suggesting optimal ion mobility. The enhanced conductivity was attributed to the increased mobility (μ), diffusion coefficient (D), and number density of mobile ions (η), all of which were maximized in the S3 sample, contributing to efficient ion transport. However, higher concentrations of LiBOB beyond 6 wt.% led to ion aggregation and a reduction in the number of free charge carriers, ultimately decreasing ionic conductivity. These findings underscore the potential of the developed GPE system for lithium-ion battery applications, demonstrating that the optimized composition (S3) can achieve high conductivity and favorable thermal properties, making it a strong candidate for advanced energy storage technologies.

Data availability

No datasets were generated or analysed during the current study.

References

Hammami A, Raymond N, Armand M (2003) Runaway risk of forming toxic compounds. Nature 424:635–636. https://doi.org/10.1038/424635b

Di Noto V, Lavina S, Giffin GA, Negro E, Scrosati B (2011) Polymer electrolytes: present, past and future. Electrochim Acta 57:4–13. https://doi.org/10.1016/J.ELECTACTA.2011.08.048

Irfan M, Atif M, Yang Z, Zhang W (2021) Recent advances in high performance conducting solid polymer electrolytes for lithium-ion batteries. J Power Sources 486:229378. https://doi.org/10.1016/j.jpowsour.2020.229378

Ulaganathan M, Nithya R, Rajendr S (2012) Surface analysis studies on polymer electrolyte membranes using scanning electron microscope and atomic force microscope. Scan Electron Microsc. https://doi.org/10.5772/34948

Mazuki NF, Fuzlin AF, Saadiah MA, Samsudin AS (2019) An investigation on the abnormal trend of the conductivity properties of CMC/PVA-doped NH4Cl-based solid biopolymer electrolyte system. Ionics (Kiel) 25:2657–2667. https://doi.org/10.1007/S11581-018-2734-9/TABLES/5

Jiang Y, Yan X, Ma Z, Mei P, Xiao W, You Q, Zhang Y (2018) Development of the PEO based solid polymer electrolytes for all-solid state lithium ion batteries. Polymers (Basel) 10:. https://doi.org/10.3390/POLYM10111237

Tu J, Wu K, Jiang J, Wu M, Hu Q, Xu G, Lou P, Zhang W (2021) A novel ceramic/polyurethane composite solid polymer electrolyte for high lithium batteries. Ionics (Kiel) 27:569–575. https://doi.org/10.1007/S11581-020-03838-5/FIGURES/6

Gu Y, Yang L, Luo S, Zhao E, Saito N (2022) A non-flammable, flexible and UV-cured gel polymer electrolyte with crosslinked polymer network for dendrite-suppressing lithium metal batteries. Ionics (Kiel) 28:3743–3759. https://doi.org/10.1007/S11581-022-04621-4/FIGURES/13

Livinus O, Ken O, Oji A, Obasi LA (2013) Effect of sodium alginate on proton conductivity of cassava starch in a microbial fuel cell. Greener Journal of Biological Sciences 3:074–083. https://doi.org/10.15580/GJBS.2013.2.120112309

Selvalakshmi S, Mathavan T, Selvasekarapandian S, Premalatha M (2018) Effect of ethylene carbonate plasticizer on agar-agar: NH4Br-based solid polymer electrolytes. Ionics (Kiel) 24:2209–2217. https://doi.org/10.1007/S11581-017-2417-Y/FIGURES/8

Khanmirzaei MH, Ramesh S, Ramesh K (2015) Effect of different iodide salts on ionic conductivity and structural and thermal behavior of rice-starch-based polymer electrolytes for dye-sensitized solar cell application. Ionics (Kiel) 21:2383–2391. https://doi.org/10.1007/S11581-015-1385-3/FIGURES/10

Shanmuga Priya S, Karthika M, Selvasekarapandian S, Manjuladevi R, Monisha S (2018) Study of biopolymer I-carrageenan with magnesium perchlorate. Ionics (Kiel) 24:3861–3875. https://doi.org/10.1007/S11581-018-2535-1/TABLES/4

Mazuki NF, Nagao Y, Kufian MZ, Samsudin AS (2022) The influences of PLA into PMMA on crystallinity and thermal properties enhancement-based hybrid polymer in gel properties. Mater Today Proc 49:3105–3111. https://doi.org/10.1016/J.MATPR.2020.11.037

Minakshi M, Mujeeb A, Whale J, Evans R, Aughterson R, Shinde PA, Ariga K, Shrestha LK (2024) Synthesis of porous carbon honeycomb structures derived from hemp for hybrid supercapacitors with improved electrochemistry. Chempluschem e202400408. https://doi.org/10.1002/CPLU.202400408

Minakshi M, Samayamanthry A, Whale J, Aughterson R, Shinde PA, Ariga K, Kumar Shrestha L (2024) Phosphorous – containing activated carbon derived from natural honeydew peel powers aqueous supercapacitors. Chem Asian J 19:e202400622. https://doi.org/10.1002/ASIA.202400622

Gunasekaran A, Sorrentino A, Asiri AM, Anandan S (2020) Guar gum-based polymer gel electrolyte for dye-sensitized solar cell applications. Sol Energy 208:160–165. https://doi.org/10.1016/j.solener.2020.07.084

Ramesh S, Liew CW, Ramesh K (2011) Evaluation and investigation on the effect of ionic liquid onto PMMA-PVC gel polymer blend electrolytes. J Non Cryst Solids 357:2132–2138. https://doi.org/10.1016/J.JNONCRYSOL.2011.03.004

Balakrishnan PG, Ramesh R, Prem Kumar T (2006) Safety mechanisms in lithium-ion batteries. J Power Sources 155:401–414. https://doi.org/10.1016/J.JPOWSOUR.2005.12.002

Aravindan V, Vickraman P (2007) A study on LiBOB-based nanocomposite gel polymer electrolytes (NCGPE) for Lithium-ion batteries. Ionics (Kiel) 13:277–280. https://doi.org/10.1007/S11581-007-0106-Y/FIGURES/4

Xiong S, Kai X, Hong X, Diao Y (2012) Effect of LiBOB as additive on electrochemical properties of lithium-sulfur batteries. Ionics (Kiel) 18:249–254. https://doi.org/10.1007/S11581-011-0628-1/FIGURES/6

Wigayati EM, Lestariningsih T, Subhan A, Ratri CR, Purawiardi I (2016) Synthesis and characterization of LiBOB as electrolyte for lithium-ion battery. Ionics (Kiel) 22:43–50. https://doi.org/10.1007/S11581-015-1531-Y/FIGURES/9

Mazuki NF, Kufian MZ, Samsudin AS (2024) Evaluation on electrochemical properties of lithium-ion battery–based PMMA-PLA blend incorporation of [EDIMP] TFSI hybrid gel polymer electrolyte. Ionics (Kiel) 30:169–182. https://doi.org/10.1007/S11581-023-05253-Y/TABLES/3

Sarmah H, Boruah B, Borah M, Shukla N, Gogoi A, Mahanta UJ, Sarmah JK, Saikia L, Deka M (2023) High ionic conductivity upon low electrolyte uptake in TiO2 nanofiber-filled guar gum gel electrolytes. Mater Chem Phys 307:128239. https://doi.org/10.1016/J.MATCHEMPHYS.2023.128239

Kundu S, Abdullah MF, Das A, Basu A, Halder A, Das M, Samanta A, Mukherjee A (2016) Antifungal ouzo nanoparticles from guar gum propionate. RSC Adv 6:106563–106571. https://doi.org/10.1039/C6RA19658F

Iqbal DN, Nazir A, Iqbal M, Yameen M (2020) Green synthesis and characterization of carboxymethyl guar gum: application in textile printing technology. Green Processing and Synthesis 9:212–218. https://doi.org/10.1515/GPS-2020-0022

Elsaeed Shimaa SM, Zaki EG, Omar WAE, Ashraf Soliman A, Attia AM (2021) Guar gum-based hydrogels as potent green polymers for enhanced oil recovery in high-salinity reservoirs. ACS Omega 6:23421–23431. https://doi.org/10.1021/ACSOMEGA.1C03352/ASSET/IMAGES/LARGE/AO1C03352_0013.JPEG

Dharaskar SA, Wasewar KL, Varma MN, Shende DZ, Yoo CK (2013) Deep removal of sulfur from model liquid fuels using 1-butyl-3- methylimidazolium chloride. Procedia Eng 51:416–422. https://doi.org/10.1016/J.PROENG.2013.01.058

Fan Z, Chen J, Guo W, Ma F, Sun S, Zhou Q (2018) In situ monitoring the moisture absorption of three ionic liquids with different halogen anions by ATR-FTIR spectroscopyhttps://doi.org/10.1016/j.molstruc.2018.03.043

Dharaskar SA, Varma MN, Shende DZ, Yoo CK, Wasewar KL (2013) Synthesis, characterization and application of 1-butyl-3 methylimidazolium chloride as green material for extractive desulfurization of liquid fuel. Scientific World Journal 2013:395274. https://doi.org/10.1155/2013/395274

Chen K, Xu W, Ding Y, Xue P, Sheng P, Qiao H, Wang S, Yu Y (2020) Mechanical and thermal properties of all-wood biocomposites through controllable dissolution of cellulose with ionic liquid. Polymers (Basel) 12:. https://doi.org/10.3390/POLYM12020361

Lestariningsih T, Wigayati E, Ratri C, Sabrina Q (2017) Study of LiBOB compound synthesis by vacuum process as lithium ion battery electrolyteshttps://doi.org/10.1088/1742-6596/817/1/012030

Noor IS, Majid SR, Arof AK (2013) Poly(vinyl alcohol)–LiBOB complexes for lithium–air cells. Electrochim Acta 102:149–160. https://doi.org/10.1016/J.ELECTACTA.2013.04.010

Yang L, Furczon MM, Xiao A, Lucht BL, Zhang Z, Abraham DP (2010) Effect of impurities and moisture on lithium bisoxalatoborate (LiBOB) electrolyte performance in lithium-ion cells. J Power Sources 195:1698–1705. https://doi.org/10.1016/J.JPOWSOUR.2009.09.056

Chowdhury FI, Khandaker MU, Amin YM, Kufian MZ, Woo HJ (2017) Vibrational, electrical, and structural properties of PVDF–LiBOB solid polymer electrolyte with high electrochemical potential window. Ionics (Kiel) 23:275–284. https://doi.org/10.1007/S11581-016-1857-0/FIGURES/12

Syafiq A, Asnawi FM, Amalina A, Azli M, Hafiz Hamsan M, Fakhrul M, Kadir ZA, Yusof YM (2020) Electrical and infrared spectroscopic analysis of solid polymer electrolyte based on polyethene oxide and graphene oxide blend (Kajian Elektrik dan Spektroskopik Inframerah kepada Elektrolit Polimer Pepejal Campuran Polietilena Oksida dan Grafena Oksida). Malays J Analyt Sci 24:682–697

Mudgil D, Barak S, Khatkar BS (2012) X-ray diffraction, IR spectroscopy and thermal characterization of partially hydrolyzed guar gum. Int J Biol Macromol 50:1035–1039. https://doi.org/10.1016/J.IJBIOMAC.2012.02.031

Zainuddin NK, Rasali NMJ, Samsudin AS (2018) Study on the effect of PEG in ionic transport for CMC-NH4Br-based solid polymer electrolyte. Ionics (Kiel) 24:3039–3052. https://doi.org/10.1007/S11581-018-2505-7/TABLES/4

Schreiber C, Ghebremedhin M, Zielbauer B, - al, Wang Y, Yang W, Wang Q, Cao Y, Xia W, Wang F, Li JH, Hu Y (2018) IOP Conference Series: Earth and Environmental Science Effect of micronization on the structure and particle size of guar gum. You may also like Interaction of xanthan gums with galacto-and glucomannans. part I: molecular interactions and synergism in cold gelled systems. The rheological performance of aqueous ceramic ink described based on the modified Windhab model. Effect of micronization on the structure and particle size of guar gum. IOP Conf Ser: Earth Environ Sci 199:52046. https://doi.org/10.1088/1755-1315/199/5/052046

Kim CS, Oh SM (2000) Importance of donor number in determining solvating ability of polymers and transport properties in gel-type polymer electrolytes. Electrochim Acta 45:2101–2109. https://doi.org/10.1016/S0013-4686(99)00426-0

Hazwan Hussin M, Bello I, Tuan ;, Hamidon S, Mohamad ;, Bakar A, Ahmad ;, Mohamad A, Haafiz M (2020) Physico-chemical and conductivity studies of microstalline chemical studies of microcrystalline cellulose (MCC) extracted from-oil palm fronds as a susceptible filler in PLA-LiTFSi polymer electrolyte. J Oil Palm Res 32:271–285. https://doi.org/10.21894/jopr.2020.0023

Dokko K, Watanabe D, Ugata Y, Thomas ML, Tsuzuki S, Shinoda W, Hashimoto K, Ueno K, Umebayashi Y, Watanabe M (2018) Direct evidence for Li ion hopping conduction in highly concentrated sulfolane-based liquid electrolytes. J Phys Chem B 122:10736–10745. https://doi.org/10.1021/ACS.JPCB.8B09439/SUPPL_FILE/JP8B09439_SI_004.CIF

Leyva-Porras C, Cruz-Alcantar P, Espinosa-Solís V, Martínez-Guerra E, Piñón-Balderrama CI, Martínez IC, Saavedra-Leos MZ (2019) Application of differential scanning calorimetry (DSC) and modulated differential scanning calorimetry (MDSC) in food and drug industries. Polymers (Basel) 12:. https://doi.org/10.3390/POLYM12010005

Kumar A, De A, Mozumdar S (2015) Synthesis of acrylate guar-gum for delivery of bio-active molecules. Bull Mater Sci 38:1025–1032

Teo LP, Buraidah MH, Arof AK (2021) Development on solid polymer electrolytes for electrochemical devices. Molecules 26:. https://doi.org/10.3390/MOLECULES26216499

Chai S, Zhang Y, Wang Y, He Q, Zhou S, Pan A (2022) Biodegradable composite polymer as advanced gel electrolyte for quasi-solid-state lithium-metal battery. eScience 2:494–508. https://doi.org/10.1016/J.ESCI.2022.04.007

Arora N, Singh S, Kumar R, Kumar R, Kumari A (2018) Ionic conductivity, SEM, TGA and rheological studies of nano-dispersed silica based polymer gel electrolytes containing LiBF4. Solid State Ion 317:175–182. https://doi.org/10.1016/J.SSI.2018.01.023

Rayung M, Aung MM, Azhar SC, Abdullah LC, Su’ait MS, Ahmad A, Jamil SNAM (2020) Bio-based polymer electrolytes for electrochemical devices: insight into the ionic conductivity performance. Materials 2020, Vol 13, Page 838 13:838. https://doi.org/10.3390/MA13040838

Tavares FC, Cholant CM, Kohlrausch EC, R. Bolzan G, Gonçalves PFB, Gil ES, Khan S, Dupont J, Avellaneda CO, Leite Santos MJ (2023) Ionic liquid boosted conductivity of biopolymer gel electrolyte. J Electrochem Soc 170:084501. https://doi.org/10.1149/1945-7111/ACE937

Guo Y, Terban MW, Moudrakovski I, Münchinger A, Dinnebier RE, Popovic J, Maier J (2023) Ion transport in semi-solid in-salt electrolytes: LiTFSI-H 2 O as a model system †. https://doi.org/10.1039/d2ta08047h

Chai KL, Aung MM, Noor IM, Lim HN, Abdullah LC (2022) Observation of ionic conductivity on PUA-TBAI-I2 gel polymer electrolyte. Scientific Reports 2022 12:1 12:1–20. https://doi.org/10.1038/s41598-021-03965-7

Abirami M, Saratha R, Shilpa R, Vinitha B (2020) Preparation and characterization of guar gum-based solid biopolymer electrolyte doped with lithium bis(trifluoromethanesulphonyl)imide (LiTFSI) plasticized with glycerol. Bull Mater Sci 43:1–6. https://doi.org/10.1007/S12034-020-02218-Z/METRICS

Azzahari AD, Abdul Mutalib NF, Rizwan M, Naceur Abouloula C, Selvanathan V, Sonsudin F, Yahya R (2018) Improved ionic conductivity in guar gum succinate–based polymer electrolyte membrane. https://doi.org/10.1177/0954008318775790 30:993–1001

Li Q, Yang H, Xie L, Yang J, Nuli Y, Wang J (2016) Guar gum as a novel binder for sulfur composite cathodes in rechargeable lithium batteries. Chem Commun 52:13479–13482. https://doi.org/10.1039/C6CC07250J

Tripathi J, Gupta S, Mishra BB (2024) Synthesis of guar gum maleate under dry conditions: reaction kinetics and characterization. Int J Biol Macromol 267:. https://doi.org/10.1016/J.IJBIOMAC.2024.131591

Laurson P, Raudsepp P, Kaldmäe H, Kikas A, Mäeorg U (2020) The deconvolution of FTIR-ATR spectra to five Gaussians for detection of small changes in plant-water clusters. AIP Adv 10:85214. https://doi.org/10.1063/5.0011700/991872

Gan F, Wu K, Ma F, Du C (2020) In situ determination of nitrate in water using Fourier transform mid-infrared attenuated total reflectance spectroscopy coupled with deconvolution algorithm. Molecules 25:. https://doi.org/10.3390/MOLECULES25245838

Abdul Rahaman MH, Khandaker MU, Khan ZR, Kufian MZ, Noor ISM, Arof AK (2014) Effect of gamma irradiation on poly(vinyledene difluoride)-lithium bis(oxalato)borate electrolyte. Phys Chem Chem Phys 16:11527–11537. https://doi.org/10.1039/C4CP01233J

Deka M, Longkumar Y, Boruah B, Sarmah H, Konwar M, Borthakur LJ (2024) Borax cross-linked guar gum hydrogel-based self healing polymer electrolytes filled with ceramic nanofibers towards high-performance green energy storage applications. React Funct Polym 195:105822. https://doi.org/10.1016/J.REACTFUNCTPOLYM.2023.105822

Aruchamy K, Ramasundaram S, Divya S, Chandran M, Yun K, Oh TH (2023) Gel polymer electrolytes: advancing solid-state batteries for high-performance applications. Gels 2023, Vol 9, Page 585 9:585. https://doi.org/10.3390/GELS9070585

Shabanov NS, Rabadanov KS, Gafurov MM, Isaev AB, Sobola DS, Suleimanov SI, Amirov AM, Asvarov AS (2021) Lignin-based gel polymer electrolyte for cationic conductivity. Polymers (Basel) 13:. https://doi.org/10.3390/POLYM13142306/S1

Acknowledgements

The authors would like to thank the Ministry of Higher Education, Malaysia (MOHE) for the FRGS research grant (FRGS/1/2023/STG05/UMP/02/2) and Malaysia International Scholarship (MIS), Universiti Malaysia Pahang Al-Sultan Abdullah (UMPSA) for the internal research grant (RDU 233001). Also, the authors gratefully acknowledge the facilities, the scientific, and technical assistance at Centre for Advanced Intelligent Materials, Universiti Malaysia Pahang Al-Sultan Abdullah and Dr. N. F. Mazuki for the help and support given for the completion of this work. In addition, grateful appreciation is extended to Eastern University, Sri Lanka, for their support and contributions.

Author information

Authors and Affiliations

Contributions

S. Aynharn: Draft preparation, Methodology, Investigation, Writing and Editing. A.F. Fuzlin: Data validation, Methodology, Writing, and Editing, Co-supervision and A.S. Samsudin: Reviewing, Validation, Conceptualization, Funding, Supervision, and Visualization.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aynharn, S., Fuzlin, A.F. & Samsudin, A.S. Correlation studies between structural and ionic transport properties of lithium-ion gel polymer electrolytes based on guar gum. Ionics 31, 509–524 (2025). https://doi.org/10.1007/s11581-024-05976-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-024-05976-6